Partner Insight: The EU's Packaging and Packaging Waste Regulation (PPWR) is a watershed moment for the packaging industry, writes Dow's Carolina Gregorio

In June, a new cohort of MEPs emerged from the European Parliament election. By September, the announcement of the new EU Commission-designates followed, introducing a fresh set of priorities around implementation of the Green Deal and strengthening EU competitiveness. As these new MEPs and Commission-designates head into the Autumn, policy momentum is building and first on the agenda is work on the EU legislative acts from the previous mandate which legislators did not have time to finalise before the elections. This includes the ones that fall under the Packaging and Packaging Waste Regulation (PPWR).

For the packaging industry, this is a watershed moment. The widely discussed and debated PPWR was approved by the Parliament at the end of April and is now following the standard legislative corrigendum process towards final approval, expected at the end of November as per the latest indications.

PPWR is a key lever in achieving the European packaging industry's circularity and delivering on Europe's net zero ambition, while enabling industry to regain competitiveness and maximise business growth opportunities. As Dow's sustainability policy and advocacy strategy director in the EMEA region, I strongly believe PPWR can be a very effective policy instrument to deliver on both Dow's and the packaging industry's circular goals. I am acutely aware of its significant potential to improve the way in which we make, use and dispose of packaging and recognise that we have an integral role to play in this as one of the world's leading materials science companies, serving customers in the packaging industry. In the coming years, it will be critical that we collaborate with policy makers and industry stakeholders to develop secondary policies that ensure smooth and practical implementation.

The role of the plastics industry

Transitioning to a circular economy for plastic packaging is at the top of our agenda at Dow. We're investing in next-generation technologies and innovative plastic materials to help ensure that more packaging can be designed for recyclability. Through our material science expertise, we are working to help enable the use of recycled plastics content in an expanded range of plastic packaging applications, including sensitive applications such as food contact packaging. In other words, we help optimise packaging circularity, ensuring the necessary functionality for end applications while minimising packaging resources and waste.

Effective regulation is key to enable this at scale. As part of the EU's Green Deal, the PPWR mandates ambitious recycled plastic content targets for all plastic packaging, driving market demand and unlocking investments to accelerate the transition to a circular economy. There is a long road ahead, but PPWR reflects an encouraging step forward for our industry and for the environment. It makes packaging the bellwether for other sectors, where circularity targets are still under consideration.

Mandatory recycled plastic content targets for packaging create the ambition needed to make a difference and stimulate the European market for secondary raw materials, defined as a priority by the new Commission to reinforce economic resilience and growth.

By 2030:

- Plastic packaging made from materials other than PET (except single-use beverage bottles) to include 10 per cent minimum recycled content.

- Single use plastic beverage bottles to include minimum 30 per cent recycled content.

- Other plastic packaging to include 35 per cent minimum recycled content.

By 2040:

- Plastic packaging made from materials other than PET (except single-use beverage bottles) to include 25 per cent minimum recycled content.

- Single use plastic beverage bottles to include minimum 65 per cent recycled content.

- Other plastic packaging to include 65 per cent minimum recycled content.

[Source: PPWR on minimum recycled content requirements - original proposals here, and final adopted text here]

Targets are technology-neutral allowing all recycling technologies to contribute towards meeting them.

Chemical recycling (also known as advanced recycling) is a complementary technology to mechanical recycling and will play a key role in meeting the goals of the PPWR. It will also play an important part in Dow's own objectives; in particular the goal of transforming waste and alternative feedstock to scale our ability to produce circular and low-carbon emission solutions.

It allows plastics which are difficult to recycle mechanically to be recycled back into virgin- quality raw materials. Crucially, plastics recycled through chemical recycling processes have the same performance and safety characteristics as virgin plastics, allowing them to be used in the same packaging solutions, including food packaging. Traditional mechanical recycling methods do not allow this at scale for contact sensitive applications. By investing in chemical recycling, alongside mechanical recycling, we can improve overall plastics recycling rates and achieve recycled content targets set out by the PPWR.

A first priority, to make the circular plastics economy happen and unleash the necessary private investments, is the full backing of the fuel-use exempt mass balance accounting method for measuring recycled plastic content targets. This fully audited approach enables the calculation of recycled plastic content in packaging, not only enabling measurement against goals but also transparency for consumers through third party certification. Perhaps most importantly, however, is that mass balance enables the scale-up of chemical recycling in existing manufacturing sites by offering a credible alternative to incineration and landfill for products that cannot be mechanically recycled.

Dow is working with the likes of Mura Technology and Plastogaz, to scale chemical recycling. We are also collaborating with recycler Valoregen to build the largest hybrid mechanical and advanced recycling plant in France, combining the advantages of both technologies. Without mass balance accounting and efficient collection schemes these technologies will not be able to be deployed at scale and we will not be able to meet the targets set in the PPWR.

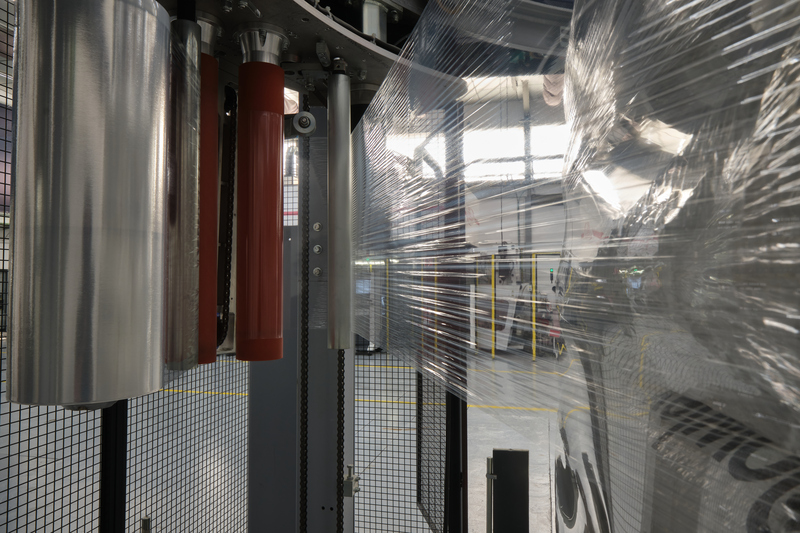

However, recycled plastic content isn't the only focus of the new EU regulation. Overall reduction in packaging waste and mandatory recyclability are vital to curbing the impact. The regulation proposes first-time mandatory recyclability for all packages from 2030, and recyclability at scale from 2035. These are based on design for recycling guidelines which are due to be defined. The regulation also mandates reuse targets for specific packaging formats and materials from 2030. In this instance, industry has raised concerns around mandatory reuse targets for stretch films for transportation packages, including some unintended cost, safety and environmental consequences. It is also collecting evidence to support potential exemptions for this specific packaging format.

Additionally the regulation outlines:

- Packaging waste reduction targets for Member States: five per cent by 2030, 10 per cent by 2035, and 15 per cent by 2040

- Criteria to avoid unnecessary packaging and optimise material use

- Bans on certain unnecessary single-use packaging formats as of 2030, expanding on existing bans under the Single Use Plastic Directive (SUPD), including bags for fruits and vegetables under 1.5 kilos as well as single-use condiments and toiletries packages for in situ consumption in hotels, restaurants and cafes

- New restrictions on Per- and Polyfluorinated Alkyl Substances (PFAS) for food contact packages

- A mandate for the Commission to examine potential mandatory bio-based plastic targets for packaging by end of 2027

- Mandatory eco-modulation of Extended Producer Responsibility (EPR) fees for packaging based on recyclability assessments as of 2030, leaving door open for additional modulation based on recycled plastic. This measure will help to boost circularity by financially incentivise front-runners in circularity.

- Mandatory reuse targets for certain packaging formats and materials as of 2030

- A mandate for the Commission to develop an impact assessment and regulatory proposal for bio-based plastics targets by 2027

The PPWR is a positive step forward, but we need a framework to scale the tools that are going to reach these ambitions. We therefore welcome the vision for the new mandate of the European Commission for the period 2024-2029 presented by Ursula von der Leyen in the European Parliament on 18 July, which proposes a new Clean Industrial Deal and a new Circular Economy Act to help create market demand for secondary materials and a single market for waste. We also welcome her new commitments to boost investments in the green transition, including through a new European Competitiveness Fund to support clean and strategic technologies. We believe that technologies in the circular economy are of strategic importance to the EU and key to reducing Europe's dependencies on virgin raw materials, boosting European economic growth and resilience while we advance our net zero Green Deal ambition and should thus be supported under the new EU agenda.

Regulators and industry need to work hand-in-hand towards a more sustainable future for packaging. Dow recognises the importance of such collaboration and is working actively across the value chain to accelerate development of circular plastic material innovations and help scale next-generation recycling technologies.

Highlights of this work include:

- Helping to enable simplification of multi-material packaging formats into mono-material polyethylene-based packages to enhance recyclability at end of life without compromising performance, safety or shelf-life. This includes developing mono-material pouches for food, home and personal care packaging.

- Introducing the REVOLOOPTM product line, which incorporates recycled plastics from mechanical recycling into non-food packaging applications, such as home care and industrial films, enabling up to 70 per cent post-consumer recycled (PCR) content in collation shrink film applications.

- Investing with innovative chemical recycling companies to scale up technologies that allow the use of recycled plastics in food contact sensitive applications

- Using recycling boosters and compatibilisers to improve the quality of recyclates in final applications, enabling higher recycled content levels

- Developing high-performance plastics that help use less packaging raw materials and enable the incorporation of PCR in technically challenging applications, such as stretch films

- Offering a broad range of bio-based plastic products with a lower carbon footprint, such as Dow's recent collaboration with New Energy Blue in US

The path forward: Collaboration is critical to success

Sitting at the intersection of customers, the value chain and policymakers, the plastic packaging industry has been advocating for a robust PPWR that gives predictability to the industry and drives investments in the circular transition towards net zero while enabling its competitiveness and growth. Going forward, we must continue to champion new technologies and innovation to ensure that targets are met, which will require significant investments.

Legislators have the power and opportunity to create the right conditions to enable a sustainable and effective transition to a circular economy. As the new PPWR regulation moves closer to adoption, it will be crucial for the entire plastic industry to assume the responsibility to ensure it becomes fully effective. Only if governments, packaging producers, raw materials producers, recyclers, waste management companies, brand owners and individuals band together - leveraging and supporting new recycling technologies and innovation – will we be able to keep up the momentum we need to transition to a truly circular packaging economy.

Carolina Gregorio is sustainability policy and advocacy strategy director at Dow Packaging & Specialty Plastics EMEA.

To find out more about how Dow is collaborating and innovating for a more circular economy for packaging, visit our website

This article is sponsored by Dow.